Variable Cost Per Unit Formula, How to Calculate, Examples

Reducing fixed costs such as rent and utilities can lower warehousing expense while optimizing logistics operations can decrease variable costs such as labor and material costs. Cost per unit plays a crucial role in the day-to-day business operations. Understanding the cost per unit is essential to determine the optimal selling price, gross profit margins, and profitability metrics. Moreover, monitoring the cost per unit over time provides valuable insights into trends and allows for a real-time analysis of costs and revenue. Cost per unit analysis allows businesses to assess the efficiency and profitability of their production processes. By calculating the average cost per unit, companies can gain valuable insights into their cost structure and identify areas for improvement.

- Mapping out your end-to-end product or service delivery process is essential.

- Seeking suppliers located in proximity to reduce the shipping costs involved in moving goods to your distribution center or warehouse can also help.

- Learn financial statement modeling, DCF, M&A, LBO, Comps and Excel shortcuts.

- Tracking and managing these costs allow businesses to determine cost-saving opportunities and improve overall operational efficiency.

- Quantity sold methods are the techniques a business uses to analyze, forecast, or manage the quantity of goods sold.

- Here is how ShipBob can turn your logistics operations into a revenue driver.

Cost Per Unit: Definition, Importance, and Tips to Reduce It

Take the case of a small ecommerce business called PetsCo, which produced 100 units of an 80 lb bag of premium dog food in February 2022. In this article, we will define cost per unit, explain why it is important, show how to calculate it, and offer actionable tips to reduce your cost per unit. how to calculate cost per unit Greg’s Apothecary produces scented candles for an average of $10 per unit. It costs Greg’s biggest competitor $8 on average to create a similar candle. Sohini is a seasoned content writer with 12 years’ experience in developing marketing and business content across multiple formats.

Optimize your logistics strategy

- The number of units sold within a specific period of time can also impact these costs.

- For example, the costs involved with delivering light-weight goods like garments or books, is different from delivering grocery and furniture.

- If the selling price falls below the production cost, the company may incur losses.

- In this guide, we’ll explain why understanding the cost per unit is important.

- The concept of operating leverage is defined as the proportion of a company’s total cost structure comprised of fixed costs.

- It refers to the average cost incurred to produce or deliver a single unit of a product or service.

Improve your operational efficiency and lower your unit costs by optimizing your delivery process with eLogii. Whether it’s a slow-selling item or obsolete inventory, having an inventory management system in place can enhance visibility so you can make wise decisions about your product catalog Law Firm Accounts Receivable Management sooner than later. Any expense incurred in the storage of unsold inventory is referred to as holding costs. These costs can range from warehousing to labor costs, to depreciation and opportunity costs. For Greg and many other retail businesses, success is heavily reliant on having a profitable cost per unit — and half of that battle is keeping your costs low.

Utilizing Cost Per Unit for Business Decision-making

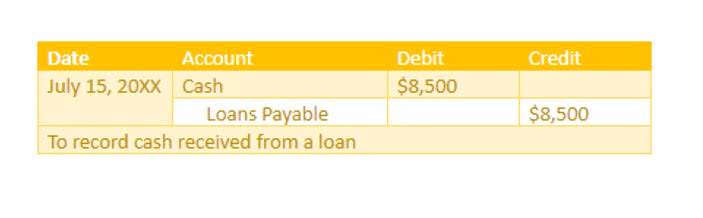

From the table, we can see that the cost per unit for both products has increased by 10%. This means that the company’s profitability and efficiency have decreased due to the increase in input prices. From the table, we can see that product A has a lower cost per unit than product B.

Comparing Cost Per Unit Across Different Products or Services

By comparing the cost per unit with the price per unit, you can assess your company’s gross profit margins. The concept of operating leverage is defined as the proportion of a company’s total cost structure comprised of fixed costs. Variable costs are directly tied to a company’s production output, so the costs incurred fluctuate bookkeeping based on sales performance (and volume). Variable costs, or “variable expenses”, are connected to a company’s production volume, i.e. the relationship between these costs and production output is directly linked.