What is minimum stock and how is it calculated?

At Interlake Mecalux, we offer Easy WMS, a WMS with multiple applications in the logistics sector. If you’re interested in ramping up the efficiency of your business’s processes and optimally monitoring stock, be sure to get in touch. However, for successful JIT implementation, accurate forecasting is crucial.

Leads to better supplier relationships

Set limitations typically dictate maximum levels, such as warehouse space, market demand, or available working capital. Optimizing inventory levels helps maximize profits while still keeping carrying costs under control. Holding too much inventory requires more space and manpower to facilitate and may prove challenging to sell within the projected free electronic filing time. Maintaining ideal inventory levels is a function companies need to plan for as early as possible. The amount of inventory on hand affects everything from overhead and storage costs to the ability to fulfill customer orders and generate profits. You can maintain more appropriate stock levels by optimizing your warehouse operations.

What are the consequences of inadequate stock levels?

At Mecalux, we offer Easy WMS, a WMS with multiple applications in the logistics sector. If you’re interested in ramping up the efficiency of your business’s processes and optimally monitoring stock, be sure to get in touch. One of our expert consultants will advise you on the best digital solution for your company. If you want to transform your warehouse into an agile, accurate installation, don’t hesitate to invest in a WMS that’s up to the task.

What is your current financial priority?

Using the information in this blog post ensures you always have enough products in stock to meet customer demand. Exceeding the maximum stock level could lead to overstocking issues like increased inventory holding costs and risk of obsolescence. Maintaining the right minimum stock level is like having a safety net for your business. You’ll know how much stock to order, keeping stockouts and backorders at bay and ensuring a smooth flow of operations.

What is sourcing: definition, how to find suppliers, & procure products

If the value reached is less than 1, this indicates that you sell, on average, less than one unit of product per day, that is, there are days when no product is sold. In addition, the minimum stock offers more security to managers, especially in extraordinary cases, such as the delay of a supplier – which could compromise its image with its loyal public. And start investigating where those missing units went (whether it’s human error, technical issues, or shrinkage) head-on.

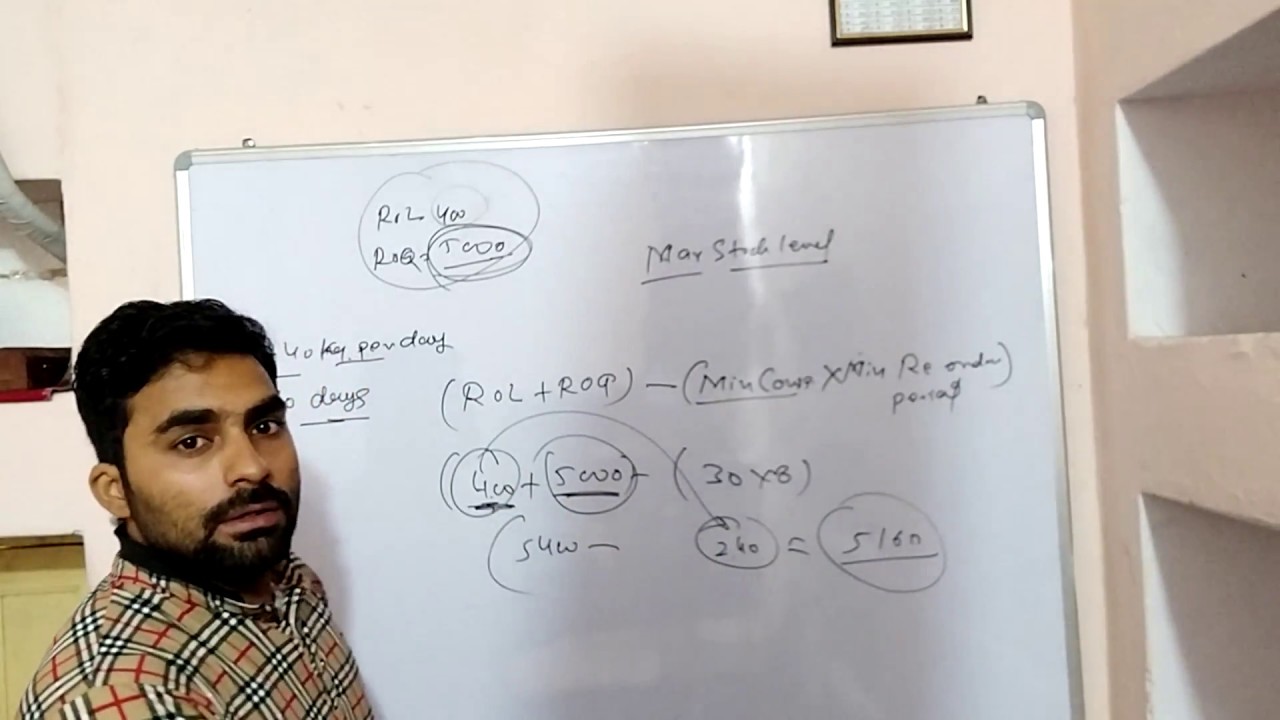

Reorder level

These formulas ensure you always have the right amount of stock—avoiding costly stockouts and minimizing excess inventory. In this guide, we’ll break down how to calculate minimum and maximum inventory levels, explore the benefits of optimizing these metrics, and explain why they’re vital for inventory control. The future of inventory management is brimming with exciting possibilities.

Plus, customizable reports and real-time data visualization make it easy to optimize stock levels and improve efficiency. Every business has to maintain a certain level of raw materials or finished goods in its store. This is done in order to sustain the continuity of production in case of raw materials and the continuity of sales in case of finished goods. For this purpose, the business must set a specific level at which it should place a new order with the suppliers of inventory. If you determine that your business sells an average of 100 widgets per day, you would multiply 100 by seven (the number of days in a week) to get your minimum inventory level of 700 widgets. The maximum inventory level refers to the highest quantity of products a company can carry before exceeding its optimum operational capacity.

- The standard deviation of demand measures the dispersion of sales in relation to the average.

- Setting minimum stock levels is essential to keeping customers happy and maintaining positive cash flow.

- Another method for calculating minimum inventory is the safety stock method.

- This process ensures enough inventory stock to fulfill sales and doesn’t fall below the minimum inventory level.

- It also reduces risk exposure to stoppages in production and sourcing problems.

As you can see, calculating your minimum inventory levels is a critical part of running a successful online business. Calculating your minimum inventory levels is a critical part of running a successful business. Regular updates and real-time tracking help maintain accurate inventory levels. In addition to optimal inventory levels, a company needs suitable suppliers for an efficient supply chain. All inventory details, such as minimum order quantities, lead times, and any non-working holidays observed by the supplier should be established. Your minimum inventory levels (or minimum stock level) are the lowest amount of a product you can have in stock and still meet customer demand.

Beyond calculating minimum inventory levels, businesses can implement various strategies and utilize tools to optimize inventory management and mitigate the risk of stockouts or overstocking. Continuous monitoring, data analysis, and process refinement are essential for optimizing inventory management practices and ensuring long-term success in maintaining optimal stock levels. Industry-specific considerations play a crucial role in determining minimum inventory levels, particularly for niche products or markets with unique demand patterns. For instance, industries with highly perishable goods may require more frequent inventory turnover and lower minimum stock levels to minimize waste. Conversely, businesses dealing with specialized products or limited production runs may need to maintain higher minimum inventory levels to ensure product availability and meet customer demand.

Even companies that deal with smaller inventory amounts need to keep track of multiple SKUs and perform several routine steps. An inventory management system can take care of many of these functions, including tracking product data in real-time, calculating inventory costs and returns, and determining the ideal reorder levels. Optimal inventory levels are the quantity of on-hand products that ensure a company can fulfill customer demand without tying up too much capital or ending up unsold. With the rule for minimum/maximum stock levels, a replenishment point is set, and, as the SKUs are used up, they are reordered to complete the inventory. Average stock level represents the optimal stock level for reliably fulfilling orders while keeping inventory costs manageable.